Your Position: Home - Solutions - Mobile Concrete Batching Plant -

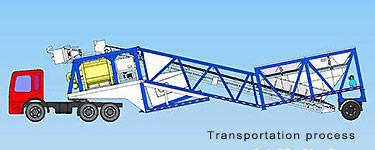

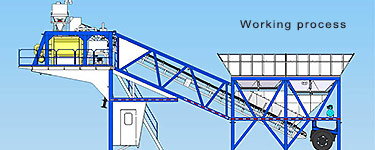

YHZS25 concrete batching plant is kind of Mobile Concrete Mixing Plant developed by HAMAC Group, based on the advantage of many models in China and overseas and the advanced technology, combing the experience of HAMAC Group in the past years. The batching unit, aggregate conveying unit, water supplying and additive agent supplying system, scaling system, mixing system, electrical control system and pneumatic system are centralized in one trailerized chassis. It has the feature of instant trailing, instant stop, reasonable structure, well function, reliable working, convenient operation, accurate scale, particularly suitable for moving sites and construction site like road, bridge, dam, airport.

Clients' Working Site

Global Case

HZS50 Concrete Batching Plant in IndonesiaCOUNTRY : Indonesia

HZS35 Concrete Batching Plant in NigeriaCOUNTRY : Nigeria

HZS35 Small Concrete Batching Plant in IndonesiaCOUNTRY : Indonesia

Advantage

Mobile concrete mixing plant which adopts advanced technologies and scientific researching results from home and abroad and combines our company’s years’ mixing station producing experience, which is a new type mobile concrete mixing station designed by our company independently .It is now one of the best mixers in China, which boasts compact and reasonable designing. Most functions of the mixing station are finished in the pulling chassis, combining aggregate, electronic weighing, mixing and lifting together.It can be stopped to run or be pulled away easily, which is convenient to move and easy to install.

1. Adopting module structure, designed as per the loading of container standard. All modules are in one trailing unit. Easy for installation and disassembly. Fast for moving.

2. Main mixing unit is JS500 double-shaft, forced concrete mixing mixer, with good mixing quality, high production efficiency. Perfect mixing can be done within ideal time period for dry-hard, half-dry-hard, plastic and concrete with any mixing ratio.

3. All scaling elements and control elements of scaling unit are imported elements and controlled by computer, guaranteeing completely accurate scale and stable function.

4. Platform or ladder is equipped to each part needing maintenance and repairing. Good for maintenance.

5. The whole system adopts complete automatic system via computer, with dynamic panel display, to show clearly of the running of each part. Visualized monitor interface provides clear and accurate observing to the site working procedure. Table or list can be print out.

6. Electrical control system adopts import elements, providing a stable and powerful function. Automatic test for the abnormal working condition, Word, sound, light alarm, easy and good for the maintenance and trouble shooting.

Specification

| Item | YHZS25 mini mobile concrete batching plant |

| Rated Productivity | 25m3/h |

| Batching Unit | PLD800 |

| Concrete Mixer | JS500 |

| Measuring Scope & Accuracy of Aggregate | 1500Kg ±2% |

| Measuring Scope & Accuracy of Cement | 300Kg ±1% |

| Measuring Scope & Accuracy of Water (by flow meter) | 200Kg ±1% |

| Discharging Height | 3.8 m |

| Outline Dimension(Operational State) (L*W*H) | 14.5m *5.6m *5.9m |

| General Power | 45.0KW (380V,50HZ) |

| Total Weight | 7700Kg |

| Control Mode | Centralized control |

| Cement Silos(Optional Parts) | 1*50T |

| Screw Conveyor(Optional Parts) | 1*φ219 screw conveyor |